Energy Saving Opportunities with Industrial Systems – Process Cooling

October 17, 2025

In the first article of this blog series, we discussed compressed air systems at industrial facilities and highlighted some of the low-cost energy saving opportunities.

In this edition, we’ll discuss process cooling systems in various industries that cool production areas to a desired temperature or directly extract heat from production equipment. Cooling is essential at many manufacturing facilities as unwanted or excess heat can affect the quality of the product and at times damage the production equipment as well. Process cooling is essential at facilities that treat (press, forge, roll or cut) primary metals to fabricate different metal parts. Food processing, data centers, plastics manufacturing and chemical processing are some of the other industries where process cooling systems are used. A typical process cooling system uses water or air as the cooling medium while systems found in colder regions could use a mixture of water + glycol solution to prevent freezing.

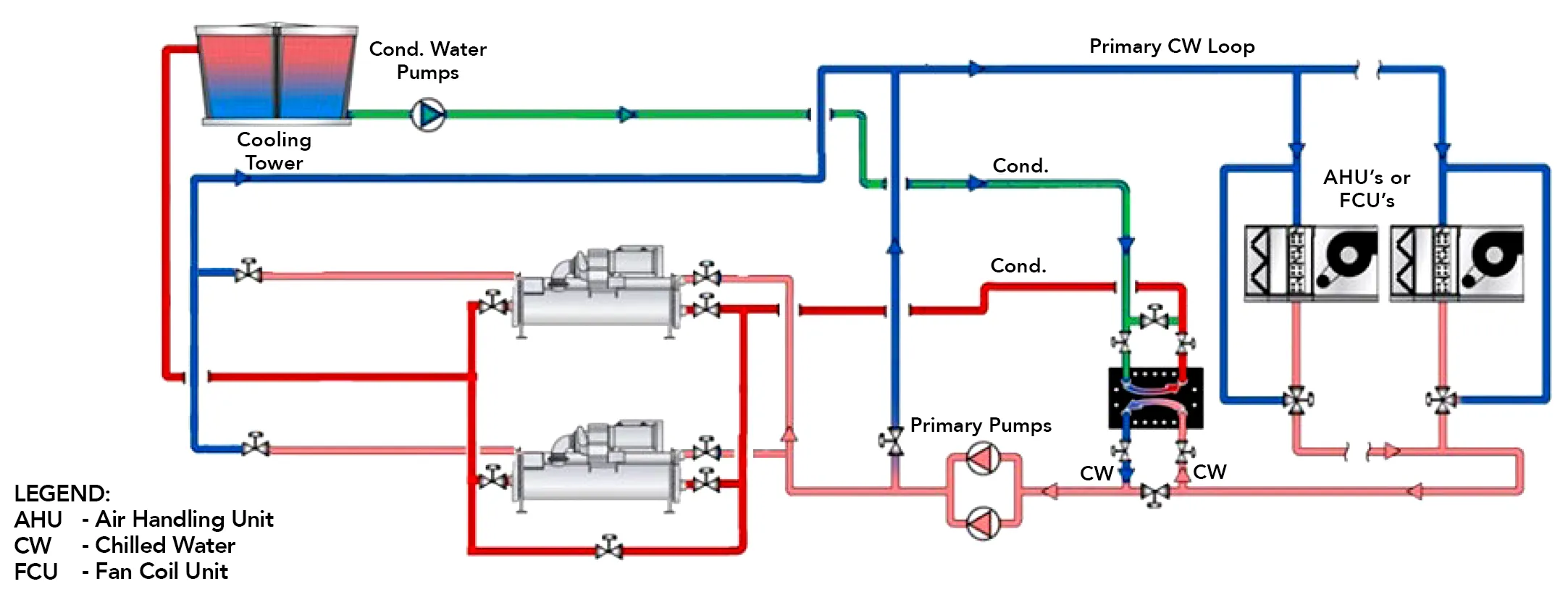

The main components of a process cooling system are cooling tower, pumps, and chiller which further encompasses condenser, evaporator, and expansion valve. The chiller acts as the heart and the major energy consumer of the entire system. While the components are similar for both process cooling systems and HVAC systems used in residences and commercial spaces, process cooling systems require precise and consistent water temperature to remove surplus heat from the processes. At manufacturing facilities, cooling systems can account for 8% of total electricity consumed.1 At data centers, as much as 40% of the total energy use can be attributed to cooling.2 Hence, it is important to operate these cooling systems at optimum efficiency as they consume high operational energy. Five of the high-impact energy conservation measures to save energy in process cooling systems are discussed below:

- Chilled Water Setpoint Temperature Reset

The chilled water temperature setpoint is the target temperature that the chiller is controlled to achieve for the water leaving the chiller, which is typically between 40⁰F and 45⁰F. Instead of setting this temperature constant throughout the year, it can be increased to a higher temperature when the cooling load is low. The cooling load could be low during off-peak production hours or when the outdoor temperature is below a certain temperature/humidity threshold. During these times of lower cooling load, the chillers and the ancillary equipment require less power. Along with improved energy efficiency, with higher setpoints chillers can also operate at their optimum performance and prolong their design life.

When the chilled water setpoint temperature is reset based on outdoor conditions, outdoor dry-bulb or wet-bulb temperature readings can be used. For example, when the outdoor temperature is above 80⁰F DB, the chilled water setpoint temperature can be 45⁰F or lower. When the outdoor temperature is below 60⁰F DB, the temperature can be 55⁰F or higher. Between 60⁰F and 80⁰F DB, the setpoint temperature can be linearly ramped between 45⁰F and 55⁰F.

Typically, for every 1F increase in chilled water setpoint temperature, the compressor power reduces by 2 to 2.5%3. This low-cost energy conservation measure can save substantial energy in regions where the outdoor conditions can fluctuate between hot and cold throughout the year. This measure is a mandatory requirement under many state or city energy codes, such as the New York City Energy Code4

- Waterside Economizer or Dry Cooler

Waterside economizers are used when the cooling medium is water (cooling tower), and dry coolers are used when the cooling medium is glycol + water mixture. Both measures aim to harness outdoor air directly to cool the medium when the conditions are favorable. This approach eliminates the need for mechanical cooling from chillers, resulting in significant energy savings. A waterside economizer works by using the cooling water loop in winter to cool chilled water without the use of chillers. This requires a dedicated plate-and-frame heat exchanger that is used only when the waterside economizer is enabled, during which time the chillers are locked out.

Source: Illinois Technical Reference Manual, Version 12, Vol.2, Pg: 671

A dry cooler works similarly but instead of cooling water, the dry cooler fans pull air from outside to cool glycol that flows through tubes or plates inside the dry cooler, which in turn cools the chilled water. A suitable temperature difference (approach) between the cooling medium (glycol) and ambient air must be determined to balance efficiency and economics of the dry cooler. Lower approach temperature (like 9⁰F) provides greater cooling efficiency but would require large and expensive dry cooling units. Conversely, higher approach temperature (like 27⁰F or above) is more economical and requires cooling units with smaller footprint but with lower efficiency5.

Both waterside economizer and dry cooler are best suited in regions where the wet bulb temperature is lower than 55⁰F for 3,000 annual hours or more. During its operation, the cost of producing chilled water is reduced by up to 70%6.

- VFD on Pumps, Condenser Fan or Cooling Tower Fan

Variable frequency drives (VFD) can control speed and torque of electric motors by varying the frequency of the input electricity. This means the electric motors used for pumps and fans can be operated at varying speeds as per requirement. A cooling system with varying loads or one that operates at part-load for much of its operating hours can benefit from using VFDs. Chilled water pumps, condenser water pumps, condenser or cooling tower fans can be retrofitted with VFDs and optimized to run at different speeds as per cooling load requirements. A control system based on differential pressure or flow sensors can monitor the cooling demand and send signals to the VFD to turn down the speed of the motor.

VFDs provide large power reduction compared to fixed-speed operation for a relatively small reduction in speed. For example, even a 10% reduction in pump speed can save 27% of the consumed power7. While VFDs can improve energy efficiency, it is important to note that VFDs are inefficient at full load operation. A VFD motor at 100% load can consume 3% more energy than a fixed speed motor at 100% load.

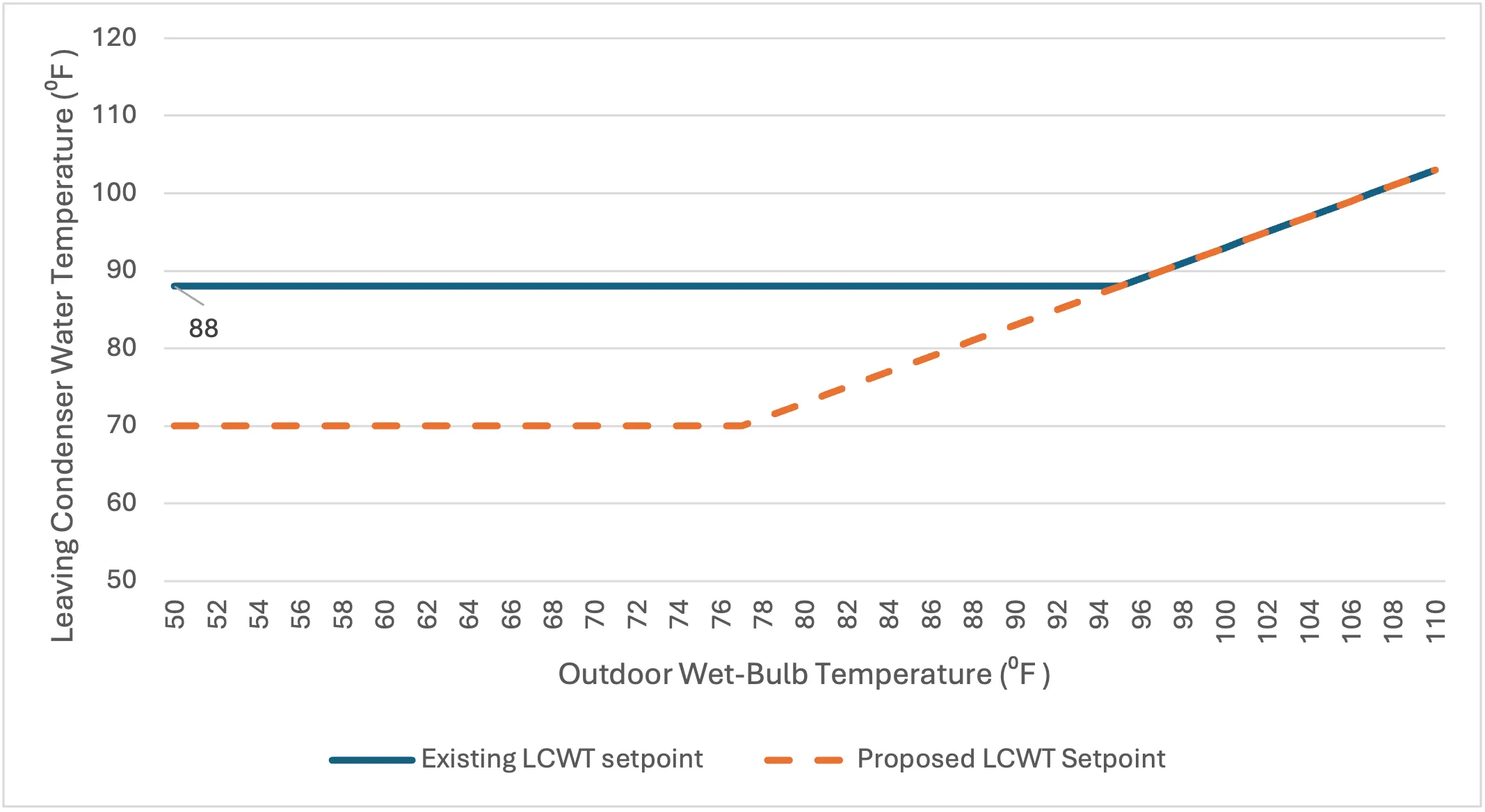

- Condenser Water Temperature Reset

Condenser water temperature reset is a common energy conservation strategy used in water-cooled chiller systems. In traditional systems, the leaving condenser water temperature (LCWT) is maintained constant even when the outdoor temperature is cooler. This results in the compressor working more than required and thereby wasting energy. When this strategy is used, the leaving condensing water temperature can be changed according to change in outdoor wet-bulb temperature plus approach. A typical approach is 7⁰F. An outdoor temperature sensor sends signals to the control system to adjust the leaving condenser water temperature setpoint. Typically, a minimum LCWT is set beyond which the condenser water temperature is not reduced to safeguard the chiller. For example, if the existing LCWT setpoint is set at 88⁰F but the minimum condenser water temperature is 70⁰F, with this measure the LCWT can be floated between 88⁰F and 70⁰F depending on outdoor wet-bulb temperature(see below chart). At regions with hot summers and cold winters, this measure can save significant amount of energy.

While using this energy conservation measure, it is recommended to have variable frequency drive for the cooling tower since the fan speed needs to be modulated to achieve the required LCWT.

- Magnetic-bearing Compressors

While this measure involves high capital expenditure when compared to other measures in this blog, it is certainly one of the most effective energy efficient measures when it comes to cooling systems. When it is time to replace a chiller or just a compressor, it is recommended to consider a high-efficiency compressor such as the magnetic-bearing compressor.

A magnetic-bearing compressor uses a permanent magnet to support and stabilize the rotation of a shaft or other moving parts without the need for physical contact. With the use of magnetic levitation, these bearings make for a frictionless operation reducing energy loss due to friction. Frictionless operation also means that the motors do not require oil lubrication eliminating maintenance needs and saving additional operating dollars.

A magnetic-bearing compressor can be installed as part of a new chiller installation or as retrofit on an existing chiller when the existing evaporator and condenser are in good condition. This measure is ideally suited for chillers that run at partial load for most of the year and may require an upgrade of controls to extract the most savings from a retrofit. Energy savings are reduced at, or near, full load. According to three case studies conducted by the Department of Energy at different naval facilities, average power savings was 49% from using magnetic-bearing compressors8.

Article written by: Karthik Radhakrishnan, Energy Engineer

- Frequently Asked Questions (FAQs) – U.S. Energy Information Administration (EIA)

- https://www.nrel.gov/news/program/2025/reducing-data-center-peak-cooling-demand-and-energy-costs-with-underground-thermal-energy-storage.html

- HVAC energy-saving strategies – Consulting – Specifying Engineer

- Chilled-Water Supply Temperature Reset (Systems 7, 8, 11, 12, and 13) | UpCodes

- air coolers Archives – Chemical Engineering

- Consider Water-Side Economizers | ENERGY STAR

- Technical publication – Using Variable Frequency Drives (VFD) To Save Energy and Reduce Emissions in New Building and Existing Ships

- Magnetic-Bearing Chiller Compressors | Department of Energy